THE BRENTA GROUP: MANUFACTURE OF MOULDS AND PLASTIC INJECTION MOULDING

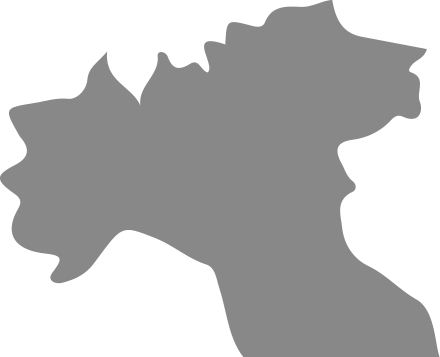

The Brenta Group is one of the leading manufacturers of complex medium to large size moulds and a manufacturer of plastic components produced using rotational multi-material injection moulding (up to 4K). Located in Molvena near Venice, the Group has more than 300 employees distributed across Italy and in México at its five manufacturing plants in Molvena (Vicenza), Rovato (Brescia), Legnago (Verona), Medolago (Bergamo), and Cd. Juárez (Chihuahua, México).

Ciudad Juárez

Chihuahua

+52 1 656257-5490

juarez@brenta.mx

Colceresa

(VI)

Rovato

(BS)

Legnago

(VR)

Medolago

(BG)

Thanks to our highly specialised “Mould and Moulding” profile, we have become the benchmark when it comes to developing solutions that make the entire manufacturing process more efficient and faster.

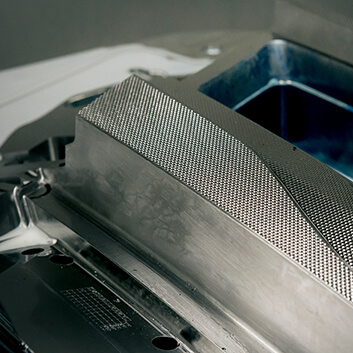

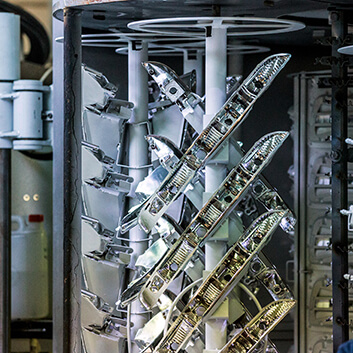

The Group is a manufacturer of precision-injection moulds that specialises in the injection moulding of plastic components for the Automotive industry (specialising in plastic components for the manufacture of headlights), Household Appliances, Sports Helmets, Garden and Design.

We pursue excellence by continuously improving our performance in terms of enhancing our in-house know-how and skills and by constantly upgrading our manufacturing process, from design to the construction of moulds, moulding and the reduction of waste, in accordance with the principles of World Class Manufacturing.

Today, Brenta is widely recognised for:

- Being a reliable partner for the supply of finished plastic components: from design to production of the mould, from injection moulding to mould finishing (through such processes as metal plating, screen printing or pad printing).

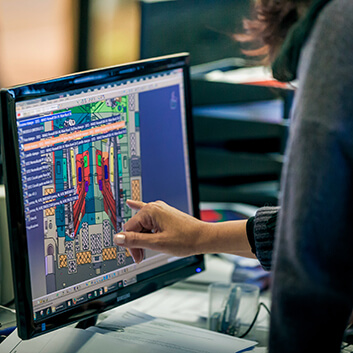

- its broad ability to interface on issues regarding co-design and engineering. Our careful eye to the needs of our customers is what most drives us to find the ideal solution and represents the first step towards manufacturing the perfect mould.

- the technical and operational efficiency of our mould production workshops. The flexibility that we have achieved during this process helps us to maintain an efficient quality control.

- The capacity to provide a full-scale customer service all over the world.

- The outstanding reputation we have gained when it comes to the quality of all our manufacturing processes.

- Our passion for innovation, which involves staff in all areas, the ongoing improvement and enhancement of our know-how and skills, continued investments in technical and organisational innovation and the careful monitoring of the supply chain are the driving principles of the way we conduct business.

We look at the future offering the best solutions in terms of design, technology, quality, competitive edge and efficiency for the production of injection moulds and injection moulding of plastic components.

World class

World classmanufacturing

Full service

Full service Global support

Global support Certified quality system

Certified quality system

Years of history

Manufacturing plants

m2 of indoor surface area

employees

200 to 1800 ton moulding machines, including 2K, 3K and 4K